The Problem

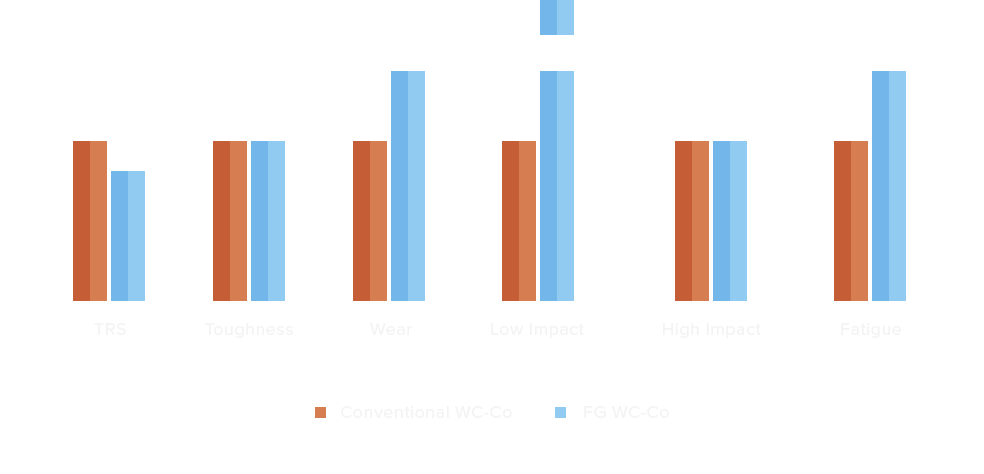

Cemented tungsten carbide has been the most widely used cutting material over many decades, but Conventional Carbide tools suffer from the trade-off between wear resistance and impact resistance.

The Solution

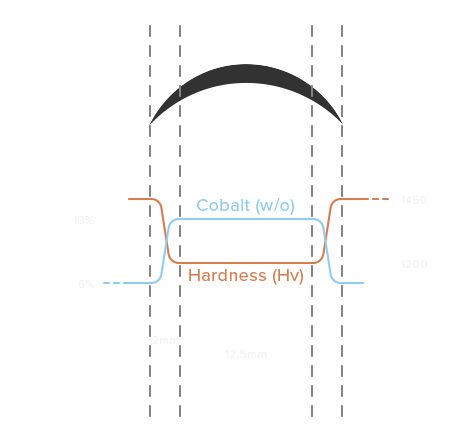

Functionally graded Carbide – with lower Cobalt content at surface for higher hardness + higher Cobalt at core for greater toughness.

Illustration of FG WC-CO

The following is an example of a dome-top cutter used on oil or mining drill bits. The cobalt gradient is evident on the polished cross section surface. The thickness of the “gradient” layer may vary from a few microns to a few millimeters, and be customized depending on the needs and part geometry.

The Technology

Carbide Tools with Enhanced Surface

Wear Resistance & Core Toughness

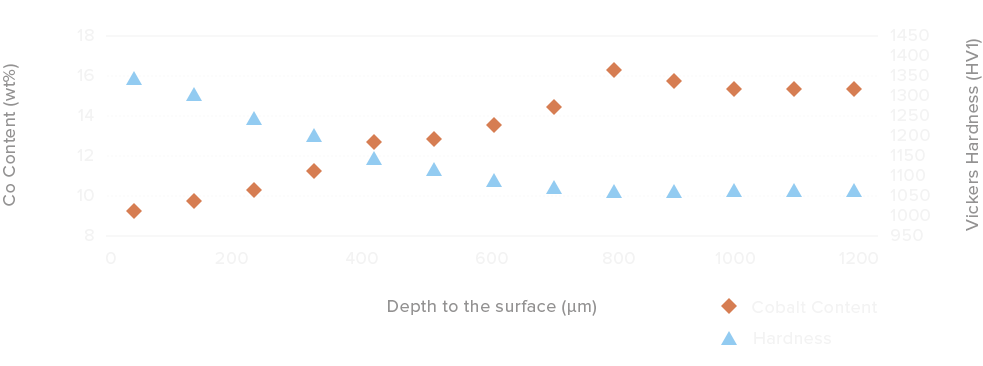

The cobalt content gradient results in the hardness gradient from surface to the interior.

Functionally Graded Cemented Tungsten Carbide

Compared to traditional WC-Co materials, FG WC-Co achieves superior wear resistance, low energy impact resistance, and compressive fatigue resistance.

How does the technology work?

Off-the-shelf standard tungsten carbide products (WC-Co) can be heat treated to produce FG WC-Co. This makes the FG WC-Co technology applicable to a wide range of industrial tools including those for mining, construction, oil and gas drilling, and manufacturing. The heat treatment is conducted in a carburizing atmosphere with proprietary processes. The heat treating furnace can be a standard vacuum sintering furnace. The following figure illustrates how standard carbide pieces can be processed in a heat treating furnace and become FG WC-Co, i.e. WC-Co tools with Heavystone Surface™

Technical Papers

The core Heavystone technical team has generated a significant number of scientific papers which have appeared in leading peer-reviewed scholarly journals. A diversified selection of these papers appear below in reverse chronological order. Because of the scientific depth and complexity (as well as in some cases the abstruse writing required for the intended to scientific audience), in order to bound the amount of study required for an overview of the subject, three of the abstracts had been highlighted in the order in which these articles might be read.

The first article by Prof. Fang and his colleagues from the University of Utah, Department of Metallurgical Engineering is particularly instructive. Any remaining questions will be addressed promptly upon application to the source under the Contact page.

Patents

Heavystone's intellectual property position is based on a broad set of patents and trade secrets. The company's issued patents are outlined below, and a number of additional patents are under development. This base of intellectual property represents a broad and deep coverage of the material, processes and products which the company provides to its partners and customers.

View Issued Patents